HERMANN MEDITECH

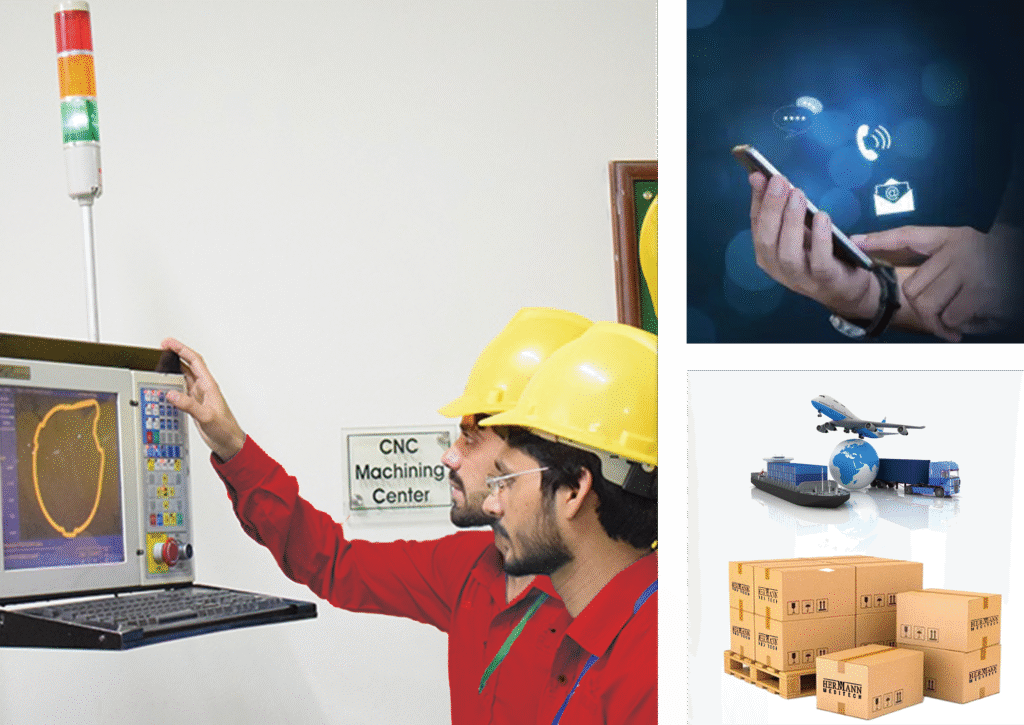

🏭 Manufacturing Strength

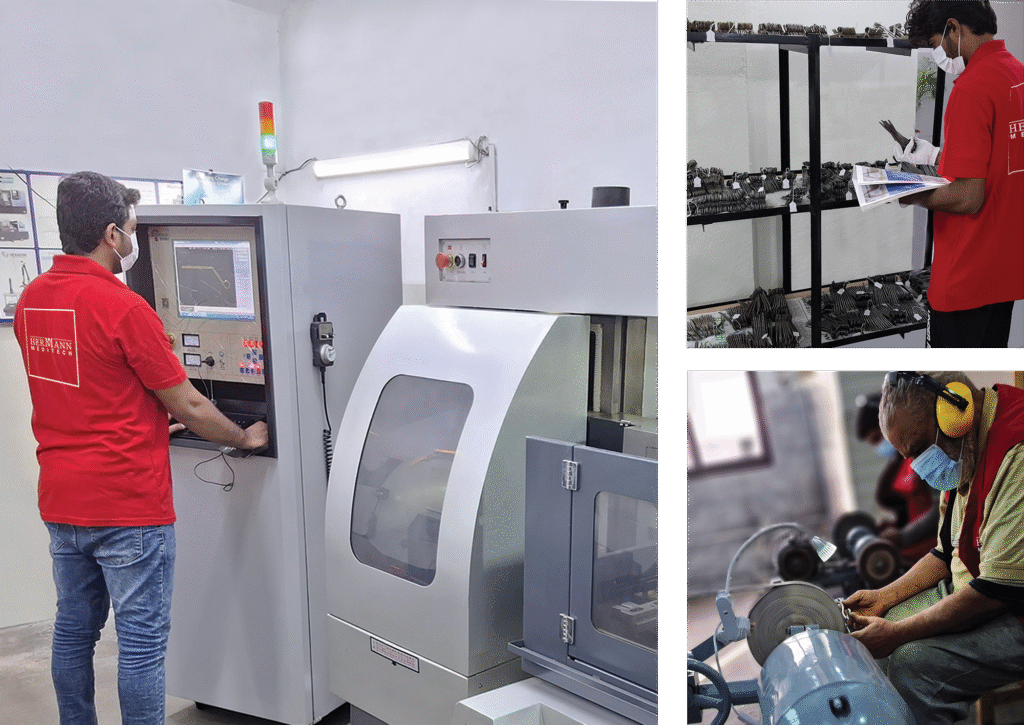

At Hermann Meditech, manufacturing excellence is the backbone of our commitment to delivering premium-quality surgical and dental instruments. Our production processes are driven by precision, consistency, and innovation—ensuring every instrument meets international standards and the expectations of medical professionals worldwide.

HERMANN MEDITECH

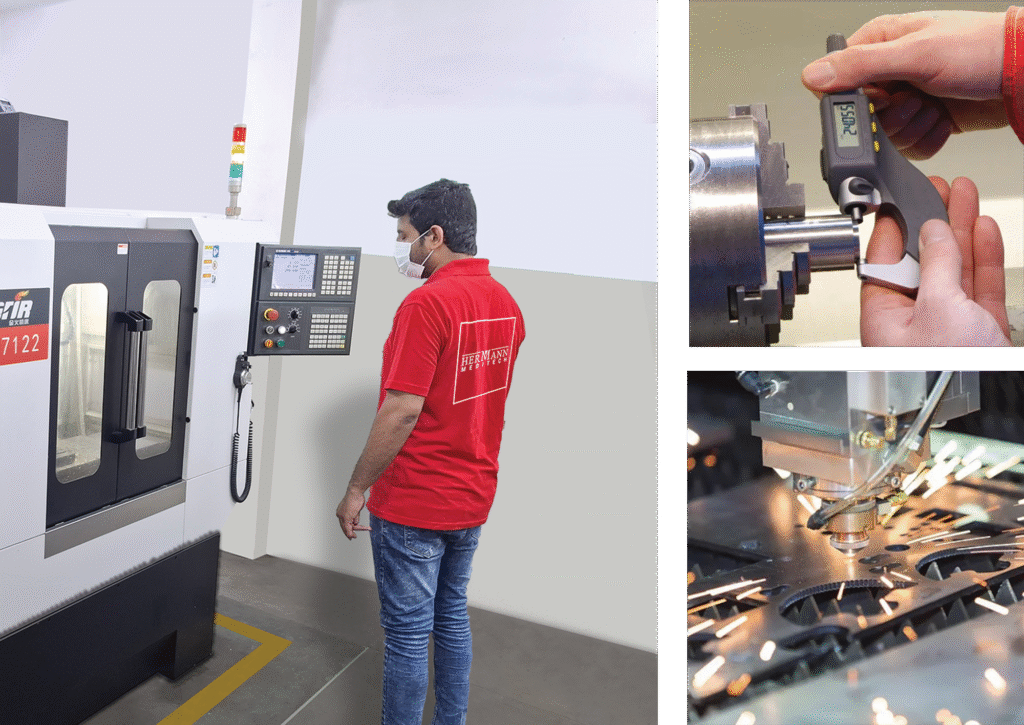

🔧 Precision Engineering

• State-of-the-art CNC machines for ultra-fine detailing

• Laser-guided cutting and marking systems

• Micro-measurement tools to ensure dimensional accuracy

• Multi-axis machining for complex geometries

• Real-time quality control during production

• Automated polishing for consistent surface finish

• Tight tolerance manufacturing down to microns

• CAD/CAM integration for seamless design-to-production workflow

HERMANN MEDITECH

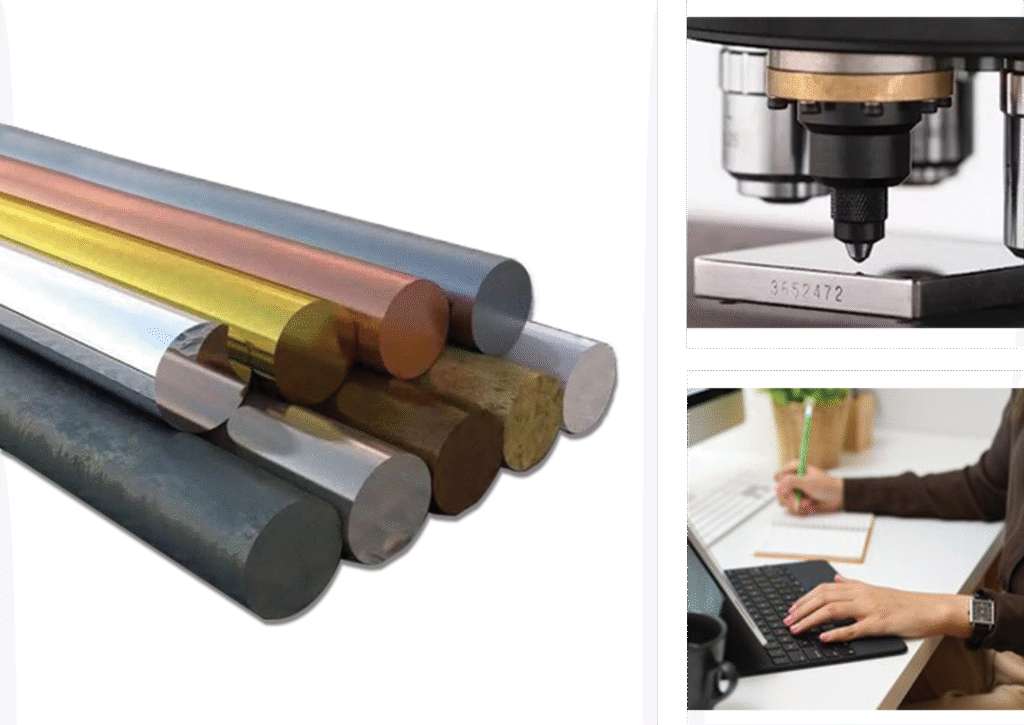

🧪 High-Grade Raw Materials

• German stainless steel for superior durability and corrosion resistance

• Biocompatible materials for patient safety and regulatory compliance

• Certified and traceable materials from trusted global suppliers

• Heat-treated for enhanced hardness and edge retention

• Non-magnetic and non-toxic properties for specialized applications

HERMANN MEDITECH

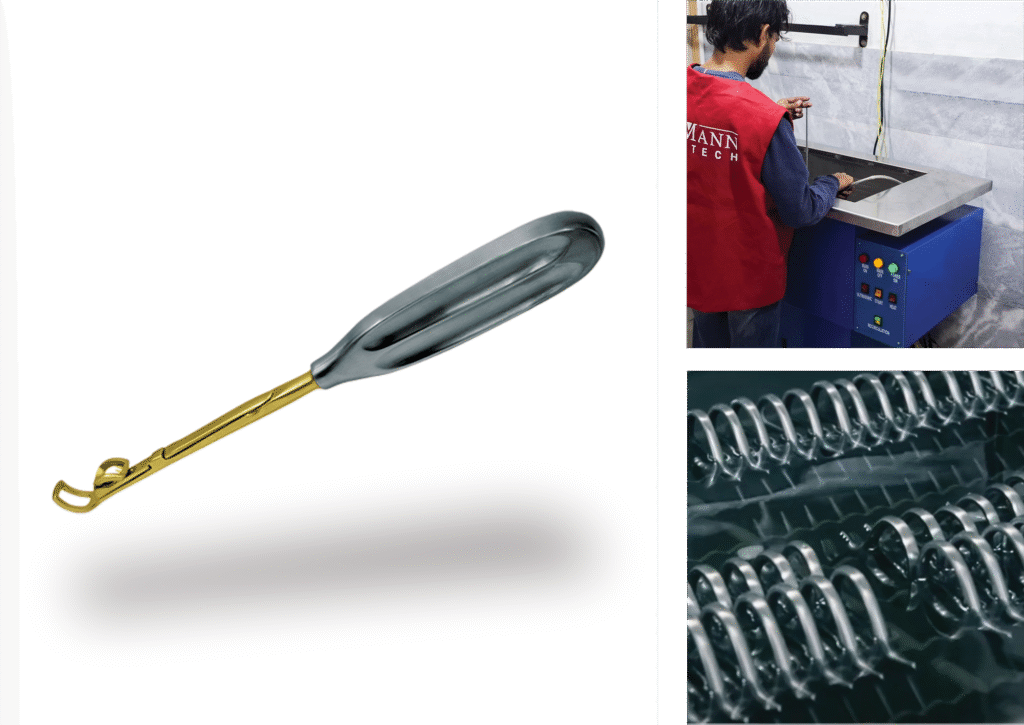

🧼 Advanced Surface Treatments

• Passivation and electro-polishing to enhance longevity

• Ultrasonic cleaning and decontamination systems

• Mirror and matte finishes available per instrument requirement

• Anti-glare coatings for enhanced visibility during procedures

• Surface roughness control for optimal grip and functionality

HERMANN MEDITECH

🧰 Skilled Hands, Smart Tech

• Hand-finishing by experienced technicians for critical instruments

• Robotic arms for repetitive precision tasks

• In-line quality checks integrated into every stage of manufacturing

• Advanced polishing for flawless surface finishes

• Digital tracking ensures full traceability from raw material to final product

HERMANN MEDITECH

📦 Scalable & Reliable Production

• Flexible batch sizes from small orders to bulk consignments

• Streamlined lead times through lean manufacturing techniques

• Dedicated customer support for seamless communication and service

• Continuous training programs for staff to ensure peak performance